Cleaning equipment and its importance in the control of Listeria in food production

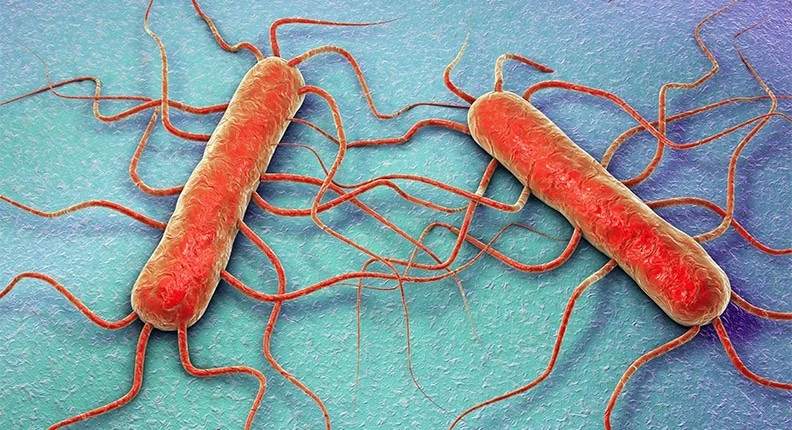

Listeria monocytogenes is a dangerous bacterium that can cause food poisoning and is a major concern in food safety.

In 2015, Public Health England reported 169 cases of listeriosis in England and Wales. While the number may seem low, the mortality rate for this pathogen is around 30%, making it very serious. The elderly and unborn or newborn babies are especially at risk. Listeria monocytogenes is the only species in the Listeria genus that is considered a human food pathogen. However, all Listeria species share similar growth conditions, so the presence of non-hazardous Listeria could indicate the presence of the harmful type.

This bacteria is commonly found in the environment and can be present in foods grown near soil, such as leafy greens. It has several characteristics that make it challenging to control:

- It can grow slowly at cold temperatures, which makes it a concern for chilled ready-to-eat (RTE) foods.

- It can survive and persist in food production environments, especially where there's plenty of moisture.

- It can form protective structures like biofilms, helping it endure harsh conditions.

These traits allow Listeria to contaminate foods even after processes that kill other pathogens, posing a significant challenge for food manufacturers.

Cleaning Equipment – Preventing Cross Contamination

Cleaning tools are often overlooked when it comes to maintaining a Listeria-free production area. Here are some important practices:

- Clean cleaning equipment after each use to prevent cross-contamination.

- Store squeegees in a sanitiser bath when not in use. Make sure the solution is refreshed regularly, as organic matter can reduce its effectiveness.

- Keep cleaning equipment off the floor. Wet tools left on the ground can support bacterial growth.

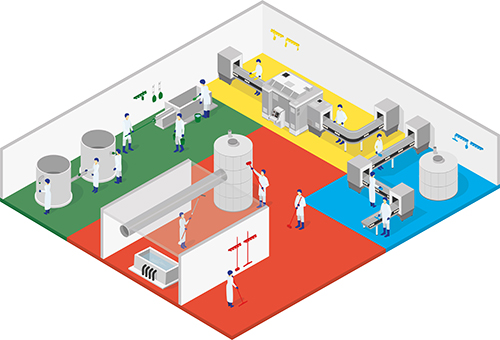

- Use color coding to ensure that equipment is used in the right areas. This helps prevent contamination between different zones.

- Replace worn-out tools, as they can easily become breeding grounds for bacteria like Listeria.

The FDA has identified four key zones for controlling Listeria in RTE facilities in the U.S., and these are also relevant to operations in the UK and EU:

Zone 1: Direct contact surfaces with food (e.g., blenders, conveyors)

Zone 2: Non-food contact areas adjacent to Zone 1 (e.g., equipment frames, drip shields)

Zone 3: Non-food contact areas not close to food (e.g., walls, drains)

Zone 4: Remote areas (e.g., offices, locker rooms)

Read more

Listeria monocytogenes is a severe foodborne pathogen. The 2017–2018 outbreak in South Africa, which resulted in over 950 cases and 180 deaths, highlights its dangers. Producers of high-risk foods must understand Listeria risks and implement proper controls. Plant managers should ensure all staff are trained and aware of hygiene practices to identify problem areas and reduce the risk of future outbreaks.

Recent blog posts

Listeria, its most common hideouts, and where to clean

If you produce chilled, ready-to-eat foods, you need to know where to clean to avoid contamination. This post covers the most common hiding spots for Listeria and how to effectively clean them.

Maximize Global Food Safety Scheme compliance

Discover what global food safety schemes like BRC, FSSC 22000, and SQF say about cleaning tool selection, use, and maintenance. Learn how to optimize your cleaning tool audit performance.

Benefit from the full Vikan experience with a Vikan site survey

A Vikan site survey ensures optimal hygiene and efficiency in high-demand sectors like food production. Discover how this tailored approach can enhance your operations.

Headband Wig Human Hair

Xuchang KANAZI Hair Products Co., Ltd. , https://www.kanazihair.com